Introduction

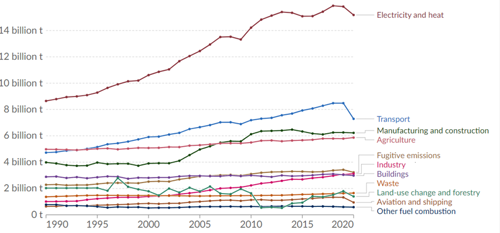

The manufacturing and construction industry is the third largest contributor to greenhouse gas (GHG) emissions worldwide, behind transport (2nd), and energy and heating (1st).[1] There have been great advancements in decarbonising transport and energy, through electric vehicles and renewable energies, however progress decarbonising the construction industry has plateaued in recent years. This is mainly due to certain aspects of the industry being particularly difficult to decarbonise, and due to the continued rise in demand within the built environment, which will be discussed further on. To achieve Net Zero, businesses and organisations must really consider the materials they use.

[1]

Sand is a key ingredient in both concrete and asphalt. Due to the ever-rising human population and global increase in urbanisation that comes with it, the demand for sand is very high. According to the UN, the number of people living in urban areas has more than quadrupled since 1950 to about 4.2 billion in 2018, and more than a half of the world’s people now live in cities [2]. Continued need for

sand through population growth will become a problem, as although seemingly abundant across beaches and sea floors, sand is still a finite resource.

Between 2008 and 2012, the UK construction minerals industry experienced an economic downturn with a considerable reduction in sales. From this, the industry has aimed to supply materials in a more sustainable manner, both economically and environmentally. The aim being to avoid another economic downturn and also in response to raising concerns regarding climate change [3].

They succeeded in improving resource efficiency following the downturn, with an increase in recycled and secondary materials, and a reduction in mineral waste. GHG emissions have reduced, within the industry, however there is a limit to the reduction due to 60% of the CO₂e emissions coming from the thermal decomposition of calcium carbonate, which is required for concrete.₂ Another challenge for the industry, in reducing the carbon footprint further, is the transport of materials. Transporting minerals too and from mines, refineries, and buyers by road has a larger environmental impact than rail and marine alternatives. This has caused a push for the use of more sustainable alternatives, both for costs and GHG emissions. [2]

GHG emissions are not the only issue to consider in the scope of sustainability however, the UN has outlined 17 sustainable development goals [4] we must adhere to for the planet to live in a truly sustainable manner. Goals 14 (Life Below Water) and 15 (Life on Land) are both very prevalent in the sand mining industry, as well as mining in general. Mining, dredging, and excavating sand comes with negative impacts on biodiversity, natural habitats, and climate resilience. Quarries remove natural habitats and minerals from the ground, dredging destroys habitats and ecosystems on the sea floor, and excavating sand from beaches and river dunes decreases the tidal defence of the coast and increases coastal erosion and the risk of floods.

The overwhelming need for sand in the construction industry directly leads to negative environmental effects, through GHG emissions and destruction of natural habitats caused by the mining of this finite resource. Despite sand being seemingly abundant on our planet, in deserts and on beaches, it is more finite than we imagine as not all sand is suitable. Although practices have been made more efficient, recycling has been increased and environmental protection acts created, the process is still unsustainable and circular alternatives to sand need to be found.

Where do we get sand from?

Despite large portions of the earth being covered in sandy deserts, the sand is unusable in construction, for example it is too fine or has poor plasticity. [5] However, there has been research carried out to treat and use it in construction. [4] For the aforementioned reasons, sand is mainly mined from quarries, dredged from waterbeds, and extracted from beaches.

Quarrying predominantly happens above ground, which involves blasting and digging large holes in the ground to extract rocks and sand. The aggregates mined are crushed, screened, and separated into size ranges. Considering the energy required at each step to mine sand from a typical quarry, the GHG emissions are calculated to be from 3.7kg to 5.51kg CO₂e per ton of sand. [6] Creating quarries for the purpose of mining sand also has negative effects on the local eco-system through the removal of natural habitats. Although the impact is less tangible than GHG emissions, it is still there to see. Such consequences from quarrying are reduction of biodiversity through the removal of minerals from the ground, land loss and changes in the landscape from excavating, noise, dust, and vibration from blasting complaints, the removal of grass leaving exposed land can impact on water levels and contribute to flooding. [7] The Mineral Products Association (MPA) are making a conscious effort to reduce such complaints and the environmental impact of quarrying. An annual sustainable

development report is now being produced as well as sustainable KPIs. The MPA have also published a Biodiversity Action Plan in place to restore quarries into priority habitats for nature conservation through the restoration of minerals. There has also been investment into switching to more renewable fuels and using carbon capture technologies to reduce the carbon footprint further. [6]

The mining of sand through dredging sea floors, lakebeds and riverbeds is usually carried out by large water vessels, known as dredgers, that either dig sand up from the bottom with a conveyor belt system or suck sand up from the bottom with large pipes. Both methods disturb the marine environment as they are removing habitats, changing the morphology of the sea bottom, and generating a plume of suspended matter in the water. [8] Dredging typically has a carbon footprint of 6.41kg and 11.73kg of CO₂e per tonne of sand for short haul and long haul dredging respectively. [9]

Illegal mining also happens worldwide. Unauthorised mining practices occur across beaches, river dunes and even inland. Even when done legally, the effects of sand mining from beaches can be devastating for the local ecosystem. Beaches have been known to be lost or greatly reduced and islands have even been lost in Indonesia due to sand mining. Sand mining in rivers has also directly caused bridges to collapse in Taiwan, Portugal, and India, where there has been loss of life.[10] There is very little data on the carbon footprint of mining sand from beaches, but it is believed to be less than quarrying due to the sand already being in the form of a fine grain and not requiring drilling and explosives. The reduction of beaches through mining reduces the local climate and storm resilience. The risks of coastal erosion, shrinking deltas, and floods greatly increases, thereby endangering the local population and habitats. [11]

Impact of Concrete

Sand is used in construction as an aggregate in concrete. The production of concrete has a very high carbon footprint due to the need for cement, which has an incredibly carbon and energy intensive production process.

The largest contributor to the carbon footprint of cement production is the process of thermally decomposing limestone, which leads to the release of a significant amount of CO₂e. This process is called calcination and contributes 467kg CO₂e per tonne of cement. [12]

Concrete is made by mixing cement, sand, and aggregate to specific ratios dependant on the end product. Despite more sand and aggregate being used in concrete than cement, [13] the majority of the carbon footprint of concrete comes from cement. The most carbon intensive method of extracting sand is 11.73kg of CO₂e pe tonne of sand8 which is eclipsed by the footprint of cement, at 663kg CO₂e per tonne of cement with all factors considered.[11] This highlights the pressing global issue of finding a way to decarbonise concrete.

How to reduce the impact?

To reduce the impact of the sector, we must cut out our reliance on virgin materials and find alternatives to cement or greatly reduce its usage. Some examples of current alternatives are:

Blast Furnace Slag is a by-product of blast furnaces. The material can replace about 70% to 80% cement and improves the durability of the concrete. Another advantage of blast furnace slag is that the production process emits less amount of heat for hydration. [14] A downside to this material is that it is a product of incineration, which involves large amounts of GHG emissions.

Micro Silica, also known as “Silica Fumes,” it is an ultrafine powder made as a by-product from silicon production. It can displace around 7% - 12% cement in concrete. [14] Micro silica is known to improve the durability of concrete by making it less permeable and increasing its compressive strength.

Recycling Aggregate is an option to help the industry decarbonise. Approximately 250 million tonnes of aggregates are used each year in the UK and 28% of that coming from recycled resources, however that is close to the achievable maximum. [15] Traditional sources of aggregates are reducing through limited access to land-based sand and gravel, putting additional pressure on the local supply of aggregates. Even if the UK doubled the volume of imported aggregates by 2035, it would only account for less than 5% of the total aggregates needed.[17] This yet again highlights the need for more sustainable and circular alternatives.

Innovative New Materials, that can replace or reduce the use of cement, are undergoing research currently. Some examples of the projects running are biocements, which grows in a similar way to coral [16], and carbon concretes which uses plant fibres to reduce the use of cement [17].

Healthcare Waste: Dr Ash Ahmed of Leeds Beckett University is currently running an Innovate UK funded project, in collaboration with NuGreen, to use healthcare waste as an aggregate in concrete. The goal of the project is to replace sand with clean/ inert waste processed and derived from healthcare waste, which has been processed into a material called floc, whilst having the benefit of diverting waste from incineration and utilising waste regarded as ‘non-recyclable’.

The NuGreen team: Rufus Henderson, Clare Atkinson, Charlie Dawson.

Conclusion

Sand is intrinsic in our built environments; it is crucial in the construction of buildings and roads. With the human population ever increasing, the demand for sand does too. Humans go to great lengths to obtain sand to keep up with the demand.

Sand, although having a far smaller carbon footprint than cement, comes with its own environmental detriment through the loss of habitat and diminished climate resilience (one could argue however, that there is a loss of habitat from cement through the creation of buildings). Both sand and cement, and the construction industry as a whole, are in desperate need of decarbonisation. It is a difficult industry to decarbonise, due to a lack of sustainable alternatives which are as effective in construction as the current materials. That is not ignore the examples of sustainable alternatives mentioned previously or other available options, they are just yet to be scaled up and backed with funding, or have legislation and regulation still to pass, or are still in early stages of research.

Not only is it important to find an alternative for sand, due to its dwindling supply, but it is imperative to also find a more sustainable production process for cement, or replacing cement all together, if the construction industry is to reach net zero. Research is being conducted into finding more of such replacements, but further investment and support is required to combat the global need for sand and concrete.

References

1 Emissions by sector: where do greenhouse gases come from? - Our World in Data

2 68% of the world population projected to live in urban areas by 2050, says UN | UN DESA | United Nations Department of Economic and Social Affairs

3 Sustainability in the UK construction minerals industry.pdf (nerc.ac.uk)

4 THE 17 GOALS | Sustainable Development (un.org)

5 The use of treated desert sand in sustainable concrete: A mechanical and microstructure study - ScienceDirect

6 NSSGAGreenhouseGasEmissionsReport04-26-21.pdf

7 MPA_SD_Report_2022.pdf (mineralproducts.org)

8 Impact of sand extraction from the bottom of the southern Baltic Sea on the relief and sediments of the seabed - ScienceDirect

9 Microsoft Word - Cover Page_TCE version.doc (thecrownestate.co.uk)

10 Sand mining: the global environmental crisis you’ve probably never heard of | Cities | The Guardian

11 As sand mining grows, Asia’s deltas are sinking, water experts warn | Reuters

12 MPA_Cement_SD_Report_2019.pdf (mineralproducts.org)

13 Concrete Mix Ratio: Ultimate Guide for Builders & DIY Enthusiasts (pro-mixconcrete.co.uk)

14 Eco-Friendly Alternatives To Traditional Concrete | Specify Concrete

15 GB aggregate need reaches four billion tonnes (theconstructionindex.co.uk)

16 Technology at Biomason - Building with Nature 17 Carbon concrete: the building material of the future? (allplan.com)

[17] Carbon concrete: the building material of the future? (allplan.com)

Written By Rufus Henderson