We’ve all been there. Opening our latest online order to be greeted with an excessive amount of packaging and feeling frustrated it’s something we cannot control. The value of online retail sales in the UK has grown from £33.24 billion in 2012 to £119.64 billion in 2021[1]

Packaging waste and CO2 emissions have grown with it. Not to mention the extreme packaging waste from our supermarket shop. Worrell and Van Sluisveld cite packaging is our biggest source of municipal waste generation with paper & cardboard, glass and plastic being substantial contributors.[2]

Figure 2: A Table depicting packaging waste and recycling, split by material, UK 2021, by thousand tonnes.

Figure 2: A Table depicting packaging waste and recycling, split by material, UK 2021, by thousand tonnes.

Many companies are turning towards more “sustainable packaging” options. But what does this actually look like? Baumann et al 2002 claims there is great confusion around what it means to provide a green or sustainable product.[3] While there has been progress within the last 20-30 years, the problem of misunderstanding sustainable consumption still hangs over us, for example, the misconceptions surrounding the true value of plastic and how biodegradable packaging really breaks down.

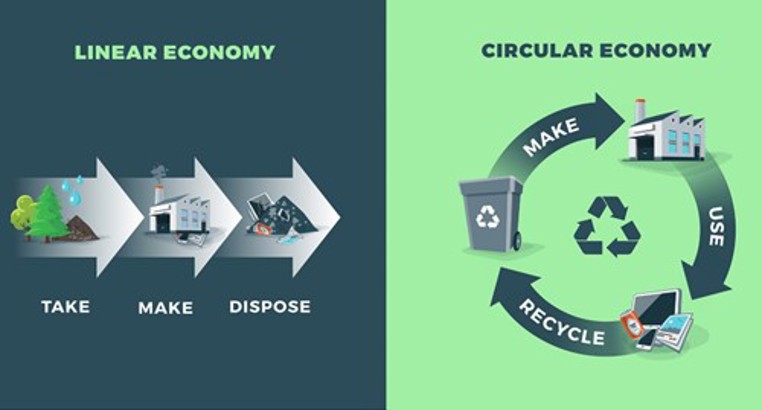

The traditional linear "take-make-dispose" model of industrial packaging, where packaging is designed for single use purposes is no longer sustainable. The circular economy offers solutions, relying less on virgin materials and keeping resources within the resource economy for longer. Here packaging is seen as a valuable commodity rather than a worthless item post consumption.[4]

Figure 3: An image depicting the crucial difference between the circular and linear economies: maintaining value for longer

What is Sustainable Packaging?

Sustainable packaging is the design and production of packaging materials and systems that meet the needs of the present without compromising the ability of future generations to meet their own needs. In other words, it's about using materials and designs that are environmentally friendly, socially responsible, and economically viable. Conserving resources, minimising energy consumption, and reducing GHG emitted should be weighed up with cost efficiency and profitability as well as ethical production, fair treatment of workers and limiting discriminatory barriers in accessing products and its packaging.

Material efficiency and designing for recycling are effective tools for delivering sustainable packaging. As there is an appetite for sustainability and an increased eco-conscious consumer base it makes good business sense to make the change and remain competitive by being cost and carbon efficient.

Material efficiency encourages brands to look at packaging with great ingenuity. Through compact, well thought out designs and process optimisation, the packaging material is reduced to only what is a necessity. For example, eliminating excessive packaging, reducing void space, fillers, packing in bulk, downgauging, choosing a lightweight material, flexible packaging and concentrating a product to ensure less packaging is required overall. Raylo, a phone leasing company, optimised its packaging by getting rid of ‘empty space’ thus reducing the weight by 25%. This saw a 11% reduction in packaging costs.[5] Their lightweight and compact designs also reduced shipping emissions, consolidated their storage, and created a lower volume of waste without affecting the practicality, durability or functionality of the packaging.

Figure 4: An image depicting a simplified stage by stage process in material efficiency.

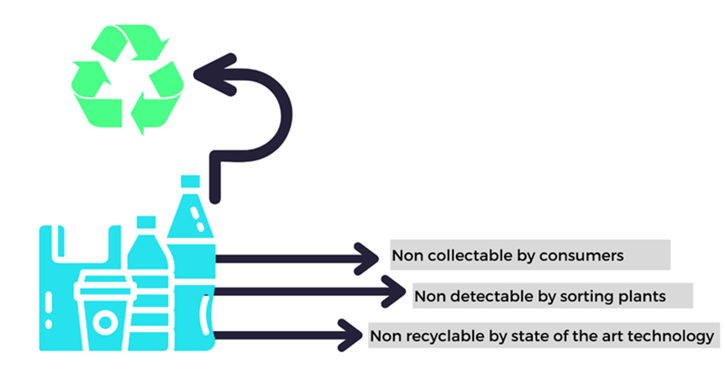

Designing for recycling increases the likelihood of packaging being repurposed post use, and feeding back into the system it came from by avoiding single use materials. At the design stage, brands should look at using materials that are in high demand for recycling, plan for compatibility with existing recycling infrastructure to ensure their materials can be easily processed and maintain good market value as a recycled commodity. Using mono-materials or easily separable materials is also preferable. While mono-materials take away the inconvenience of separation if the different packaging materials can be disassembled easily.

Figure 5: The importance of designing for recycling to avoid losing the value of a material prematurely.

The recycled product could be returned to the brand manufacturer and manufactured into operating packaging once again. Lush, a cosmetic company, has a sustainability initiative whereby customers are encouraged to return their empty containers to a store to be refilled or recycled with the incentive of a free face mask after returning 5 containers.[6]

Figure 6: The containers eligible for return to a Lush store as part of the recycling programme.

While recycling is an important component of a sustainable packaging system, it alone cannot solve the problem of excessive packaging waste. Furthermore, not all packaging materials can be recycled nor are all recycling systems efficient due to contamination issues. Therefore, a more comprehensive approach that includes the prevention of using unnecessary materials, and reducing and reusing materials is needed beyond just designing for recycling.

Fundamentally, we need substantial investment in education, knowledge sharing and infrastructure to power systematic behavioural change in consumers and producers. This will ensure long lasting behavioural change could succeed and guarantee we maximise the value of materials in our economy. For example, improving systems for the collection, recycling, and repurposing of packaging materials.[7] This should be physical infrastructure for recycling, technology, products, and services. As infrastructure tends to have a “lock in” character, it’s necessary to frame consumer behaviour throughout the ‘use’ phase and view using the infrastructure as a last resort.

Figure 7: The need for recycling infrastructure that can cope with different types of plastic and high volume of consumption.

The blame for this packaging problem often lands solely on our own consumption habits rather than those who decide how our orders are packed and what with. This seems unfair without the right knowledge or ability to save CO2 emissions and prevent waste. Akenji argues that true sustainable packaging can only be achieved by analysing the roles and responsibilities of each stakeholder in the packaging value chain. While customers are at the centre of the consumption process, they don’t carry a great deal of influence when it comes to key decision making.[8] It seems only sensible we examine how it’s sourced, designed, processed, and developed rather than criticising the consumer as cosmetic changes in individual behaviour will only get us so far. For real change, sustainable consumption should modify attitudes, along with utilising systems and infrastructure that facilitate or constrain behaviour.

A major challenge with sustainable packaging i.e., material efficiency and designing for recycling lies in securing collaboration between manufacturers, recyclers, government agencies and other stakeholders within the supply chain to ensure consistency exists between the design and infrastructure capabilities as well as consistency in recycling standards.[9]

Networking and Supply Chain Collaboration.

Robert Lilienfeld (Executive Director of SPRING, The Sustainable Packaging Research, Information, and Networking Group) argues “our current politics and political system do not promote or reasonably allow for the collaborative thinking regarding environmental goals nor is there much chance that compromises can be reached”.[10] The lack of support and transparency in starting conversations internally, between businesses or across the supply chain means actioning sustainable initiatives is difficult as there is little knowledge sharing on best practices.

The only way to encourage sustainable packaging as a standard business practice is to create a culture that is homogenous on circular thinking, where there is a strong sense of commitment and collaboration between industry, government, environmental groups and the public to action a shared, common objective.

Figure 8: Collaboration across the supply chain, government bodies , environmental groups and the public to achieve a mutual goal.

Government policy should look to protect the environmental policies of businesses. There needs to be a constant dialogue with their supply chain to ensure manufacturing partners are dedicated to operating a sustainable practice, as it creates opportunities to instil best practices among these stakeholders - for example, collaborating with environmentally conscious companies and suppliers. The environmental impact will not only be reduced for their operations but also for their suppliers and partners. This can help build a more sustainable supply chain, creating consistency for their business model. It also allows companies to be better positioned to face the demand for more sustainable products when all facets of the business are aligned. With a well embedded sustainability mindset, a culture of growth can be created.

Brands then communicating and educating their customers on how to responsibly use and dispose of packaging will ensure that sustainable consumption becomes everyone’s challenge. If there is confusion surrounding sustainable packaging, this lack of knowledge only promotes inaction. [11] Osterhaus, 1997 states policymakers need to be mindful of the attitude-behaviour gap within their consumer base. We need a facilitating system to bridge this gap, to translate the desire for action into a tangible change. This may include incentives for participation, clear standards to guide consumers as well as producers, and regulatory and economic frameworks that enable or constrain consumer choice i.e., nudging them towards more sustainable consumption.[12]

Figure 9: Waste bins guiding correct segregation behaviour with recognisable icons and designated colours for each bin.

It can be difficult to incentivise engagement, and motivation for habit change or straying from cultural norms when there is an inconvenience factor i.e., ‘take your own’ initiatives or feeling judged for overestimating the recyclability of certain types of packaging, such as assuming that all plastics can be recycled.[13] Systematic behaviour change campaigns can look to overcome this. This kind of change can be assisted by reducing disparities in regulations and creating a more standardised approach to sustainable initiatives and other areas of business where possible. We need to create a greater sense of urgency for transparency in statistics surrounding the environmental impact of packaging.[14] This includes improved guidance and enforcement of packaging optimisation as well as reporting obligations.

The need for networking and supply chain collaboration can be supported by an extended producer responsibility (EPR) policy and makes sustainability more than just ‘a nice to have.’ Under EPR, producers are required to take financial and/or physical responsibility for the disposal or recycling of their products.

The bottom line is coordination, cooperation and collaboration between multiple stakeholders including manufacturers, retailers, consumers, and government is essential. But invigorating change like this is difficult if brands are apathetic towards making environmental improvements. If this stagnant attitude exists within policy and legislative structures, it’s hard to keep businesses accountable.

Delivery Alternatives: Out-of-Home (OOH) delivery

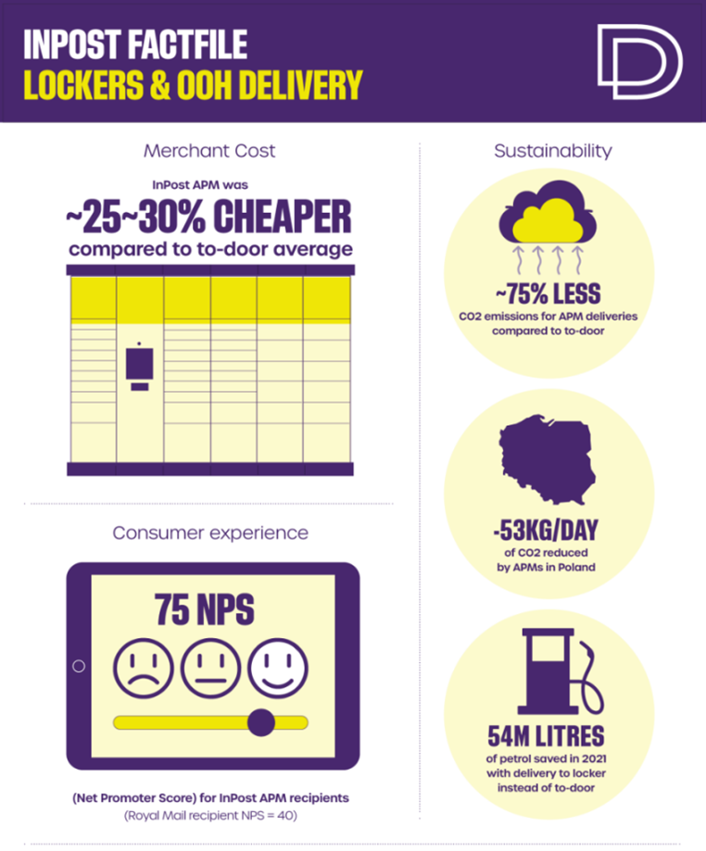

Some e-commerce companies are exploring alternative delivery models, such as consolidated delivery and locker systems, which can reduce the environmental impact of shipping. Many delivery companies like DPD and Evri will now give you an estimate of how much CO2 you are saving by choosing a locker over home delivery. These lockers are normally located in easily accessible locations like supermarkets, it could be a nudge in the right direction to bring down the carbon footprint of packaging without compromising too much on convenience. If you are doing your weekly shopping, why not pick up your online order at the same time?

Figure 10: InPost, who have recently expanded in their locker system in the UK, showcasing the savings of C02 emissions and petrol without harming customer experience.

Innovative Technologies

Berger, et al 2007, argued that change towards environmental value and social good is fostered by market-driven product innovation and new technologies rather than regulation alone.[15] Smart labels, RFID tags, and QR codes have the potential to support the transition to a circular economy by improving product traceability, reducing food waste, and facilitating recycling. The struggle here is the need for standardization, the high upfront cost, the cost of continued maintenance and the technical feasibility of scaling such technology.[16]

Plastic and Sustainable Packaging

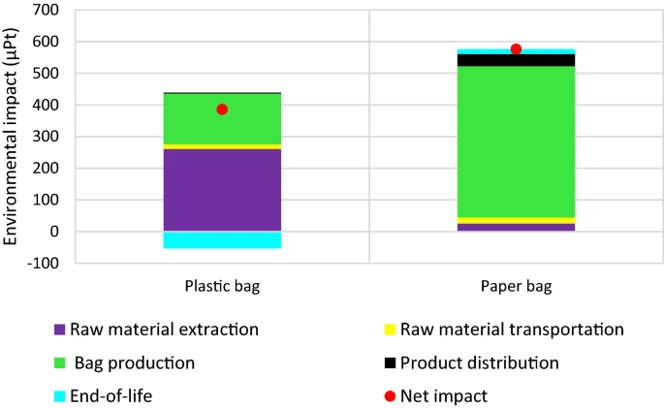

Replacing plastic with paper/cardboard due to the latter being perceived as higher in environmental credentials would be a poor move towards more sustainable consumption. A Life Cycle Analysis (LCA) will show this. LCAs consider the environmental impacts of a product throughout its entire lifecycle, from the extraction of raw materials through to the production, use, and ultimate disposal of the product. This all-encompassing data allows the sustainability credentials of one material to be directly compared to an alternative. These LCAs can inform decision making as the green credentials of the best performing packaging can be backed by good measurable data and well researched science. While paper has a higher recyclability rate than plastic, the water used, the energy required to extract raw materials and the volume of pulp waste makes it the inferior choice.

Figure 11: LCA data comparing the energy and freshwater used, GHG produced and municipal waste generated by paper v plastic bags.

There is a worrying trend whereby companies are celebrating ‘100% plastic free packaging’ and embedding this in their sustainability reports and packaging policies. This is a great approach in terms of eliminating unnecessary and excessive packaging but if it’s replaced with an alternative material net zero will never be achieved. As Neil Shackleton (multi-channel packaging & supply chain expert) wrote in a LinkedIn article, ‘decisions on sustainable packaging should be made on fact (Life Cycle Analysis) not on emotion’ in order to deliver truly sustainable environmental benefits.[17] Integrated product policies (IPP) support the value of LCAs by incorporating them into the policy framework to promote sustainable production and consumption of goods.

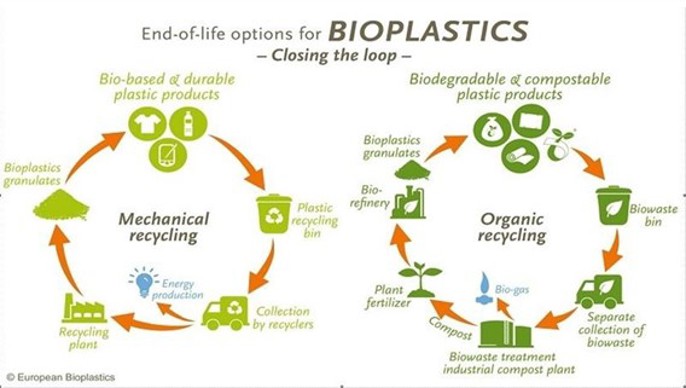

Substituting packaging for ‘compostable’ materials like hemp, bamboo and bioplastics are not necessarily sustainable nor will they solve the plastic pollution problem.[18] The raw materials typically cost more and while regulations are tightening on what companies can describe as ‘biodegradable’ the lack of easily accessible infrastructure prevents the loop from being closed. Even with ‘home composting’ this packaging doesn’t properly break down outside the correct vessel. Compostable packaging demands certain conditions that aren’t always met where the waste ends up. The absence of facilities and seamless collection systems in place works against it, and when placed in the general waste stream it secretes carbon and causes more emissions than plastic alternatives. It’s cited that the lack of infrastructure struggles to be scalable because of innovative technologies lagging behind, and the economic feasibility of such projects. Businesses are better off putting their resources into making non bioplastics more easily recyclable.[19]

Figure 12: How biodegradable and compostable plastic products can be successfully recycled by organic means.

Conclusion

To conclude, Ottoman 2006 stated that no packaging solution is going to have zero impact on the environment, the carbon footprint is different at each stage of a product’s life cycle and is product dependent thus we need to apply sustainable principles in a bespoke manner.[20] McKinsey and Company (2008) found that 60% of executives took environmental sustainability into account when developing and marketing new products and thus sustainability is seen as strategically important for the success of a business. [21]

Characteristics for success in delivering sustainable packaging include strong collaboration across the supply chain on delivering sustainable consumption supported by standardised regulatory obligations to reduce your company’s carbon footprint, investment in future-proofed infrastructure, and innovative thinking following the principles of the circular economy. With the right network sharing the same goal there is more likely to be alignment in delivering engaging consumer education on sustainable consumption and a willingness to invest in the right infrastructure.

Bibliography

[1] Published by Daniela Coppola and 28, F. (2023) UK online retail sales 2012-2022, Statista. Available at: https://www.statista.com/statistics/315506/online-retail-sales-in-the-united-kingdom/ (Accessed: April 11, 2023).

[2] Published by Worrell, Ernst, and Mariësse A. E. van Sluisveld. “Material Efficiency in Dutch Packaging Policy.” Philosophical Transactions: Mathematical, Physical and Engineering Sciences, vol. 371, no. 1986, 2013, pp. 1–15. JSTOR, http://www.jstor.org/stable/23364173. (Accessed 11 Apr. 2023).

[3] Published by Akenji, Lewis, et al. “Is the Customer Really King?: Stakeholder Analysis for Sustainable Consumption and Production Using the Example of the Packaging Value Chain.” Sustainable Consumption and Production in the Asia-Pacific Region: Effective Responses in a Resource Constrained World, Institute for Global Environmental Strategies, 2010, pp. 23–46. JSTOR, http://www.jstor.org/stable/resrep00868.11. (Accessed 11 Apr. 2023).

[4] Silva, N. and Pålsson, H. (2022) “Industrial packaging and its impact on sustainability and Circular Economy: A Systematic Literature Review,” Journal of Cleaner Production, 333, p. 130165. Available at: https://doi.org/10.1016/j.jclepro.2021.130165.

[5] Raylo Sustainability Report 2021 (2021) Raylo. Available at: https://assets.website-files.com/5ca6f1703977261264f0212e/60ca1c7352f4addce0a3ab3a_Raylo%20June%202021%20Sustainability%20Report.pdf (Accessed: April 11, 2023).

[6] Lush Fresh Handmade Cosmetics: Vegetarian & Cruelty Free (no date) Lush. Available at: https://www.lush.com/uk/en (Accessed: April 11, 2023).

[7] Published by Akenji, Lewis, et al. “Is the Customer Really King?: Stakeholder Analysis for Sustainable Consumption and Production Using the Example of the Packaging Value Chain.” Sustainable Consumption and Production in the Asia-Pacific Region: Effective Responses in a Resource Constrained World, Institute for Global Environmental Strategies, 2010, pp. 23–46. JSTOR, http://www.jstor.org/stable/resrep00868.11. (Accessed 11 Apr. 2023).

[8] Published by Akenji, Lewis, et al. “Is the Customer Really King?: Stakeholder Analysis for Sustainable Consumption and Production Using the Example of the Packaging Value Chain.” Sustainable Consumption and Production in the Asia-Pacific Region: Effective Responses in a Resource Constrained World, Institute for Global Environmental Strategies, 2010, pp. 23–46. JSTOR, http://www.jstor.org/stable/resrep00868.11. (Accessed 11 Apr. 2023).

[9] Design for Recycling of Packaging Materials" by R. C. Rowe

[10] Lilienfeld, R. (2023) The cultural dimension of policy and packaging sustainability, plasticstoday.com. Available at: https://www.plasticstoday.com/recycling/cultural-dimension-policy-and-packaging-sustainability (Accessed: April 11, 2023).

[11] Lilienfeld, R. (2023) The cultural dimension of policy and packaging sustainability, plasticstoday.com. Available at: https://www.plasticstoday.com/recycling/cultural-dimension-policy-and-packaging-sustainability (Accessed: April 11, 2023).

[12] Published by Akenji, Lewis, et al. “Is the Customer Really King?: Stakeholder Analysis for Sustainable Consumption and Production Using the Example of the Packaging Value Chain.” Sustainable Consumption and Production in the Asia-Pacific Region: Effective Responses in a Resource Constrained World, Institute for Global Environmental Strategies, 2010, pp. 23–46. JSTOR, http://www.jstor.org/stable/resrep00868.11. (Accessed 11 Apr. 2023).

[13] Published by Akenji, Lewis, et al. “Is the Customer Really King?: Stakeholder Analysis for Sustainable Consumption and Production Using the Example of the Packaging Value Chain.” Sustainable Consumption and Production in the Asia-Pacific Region: Effective Responses in a Resource Constrained World, Institute for Global Environmental Strategies, 2010, pp. 23–46. JSTOR, http://www.jstor.org/stable/resrep00868.11. (Accessed 11 Apr. 2023).

[14] Hafsa, F. et al. (2022) “A typology and assessment of innovations for circular plastic packaging,” Journal of Cleaner Production, 369, p. 133313. Available at: https://doi.org/10.1016/j.jclepro.2022.133313.

[15] Dangelico, R. M., & Pujari, D. (2010). Mainstreaming Green Product Innovation: Why and How Companies Integrate Environmental Sustainability. Journal of Business Ethics, 95(3), 471–486. Available at: http://www.jstor.org/stable/40785195

[16] Published by Daniela Coppola and 28, F. (2023) UK online retail sales 2012-2022, Statista. Available at: https://www.statista.com/statistics/315506/online-retail-sales-in-the-united-kingdom/ (Accessed: April 11, 2023).

[17] Shackleton, N. (2020) Decisions on sustainable packaging should be made on fact, not on emotion, LinkedIn. Available at: https://www.linkedin.com/pulse/decisions-sustainable-packaging-should-made-fact-neil/ (Accessed: April 11, 2023).

[18] Published by Akenji, Lewis, et al. “Is the Customer Really King?: Stakeholder Analysis for Sustainable Consumption and Production Using the Example of the Packaging Value Chain.” Sustainable Consumption and Production in the Asia-Pacific Region: Effective Responses in a Resource Constrained World, Institute for Global Environmental Strategies, 2010, pp. 23–46. JSTOR, http://www.jstor.org/stable/resrep00868.11. (Accessed 11 Apr. 2023).

[19] Weiss, M. et al. (2012) “A review of the environmental impacts of Biobased Materials,” Journal of Industrial Ecology, 16. Available at: https://doi.org/10.1111/j.1530-9290.2012.00468.x.

[20] Dangelico, R. M., & Pujari, D. (2010). Mainstreaming Green Product Innovation: Why and How Companies Integrate Environmental Sustainability. Journal of Business Ethics, 95(3), 471–486. Available at: http://www.jstor.org/stable/40785195

[21] Dangelico, R. M., & Pujari, D. (2010). Mainstreaming Green Product Innovation: Why and How Companies Integrate Environmental Sustainability. Journal of Business Ethics, 95(3), 471–486. Available at: http://www.jstor.org/stable/40785195

Written By Charlie Dawson